Silver Catalyst for Formaldehyde Production – High Efficiency & Eco-Friendly Solution

- Model

- SYAMCAT JQY 101

Item specifics

- Active component:

- Silver

- Lifetime/month:

- 3-6 month

- Reaction Temperature:

- Approximately 600-720°C

Review

Description

Description of Silver Catalyst for Formaldehyde

Key Features of Silver Catalyst:

1.High Purity

2.High Specific Surface Area

3.Low Bulk Density

4.Long Catalyst Life

5.Wide Range of Particle Sizes

Silver catalysts are widely used in processes such as methanol oxidation to formaldehyde and ethylene to ethylene oxide.

Applications of Silver Catalysts for Formaldehyde

Methanol to Formaldehyde: Used in the oxidation of methanol to formaldehyde, a key chemical in resins and plastics.

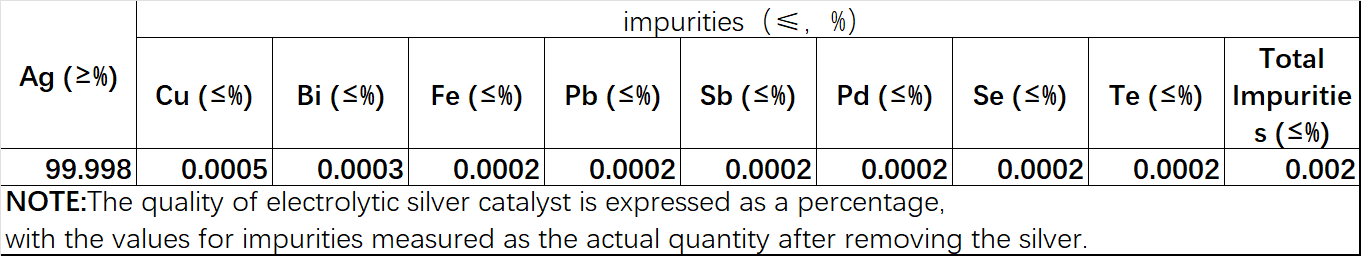

Specification of Silver Catalysts for Formaldehyde

Benefits of Silver Catalysts for Formaldehyde

1.Extremely High Specific Surface Area

2.Good Thermal Stability

3.Low System Resistance

4.High Purity

5.Strong Poisoning Resistance

6.Good Mechanical Stability

7.Longer Catalyst Life

8.Increased Formaldehyde Yield

9.Higher Methanol Conversion Rate

10.Low Formic Acid Generation Rate

Technical Service of Silver Catalysts for Formaldehyde

Inspection of Used Catalysts: Evaluation of used catalysts.

Catalyst Melting & Refining: Restoration of used catalysts.

Chemical Analysis: Analysis with certification.

New Catalyst Production: Custom catalyst manufacturing.

Fraction Sieving: Sifting catalysts into optimal sizes.

Process Diagnostics: Analysis to optimize customer processes.