Fe Mo Catalyst for Formaldehyde

- Model

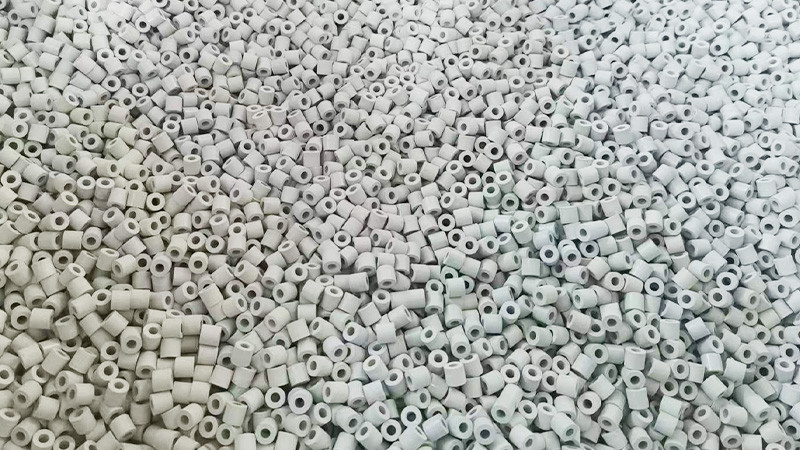

- SYAMCAT JQ116/SYAMCAT JQ216/SYAMCAT JQ316

Item specifics

- Active component

- Fe-Mo oxide

- Color

- Light green

- Lifetime/month

- 12-24

Review

Description

Description of Fe Mo Catalyst for Formaldehyde

Fe Mo Catalyst for Formaldehyde

Fe Mo Formaldehyde Catalyst is a kind of iron molybdenum-based catalysts,which can be used to improve the yields of formaldehyde.

SYAMCAT catalyst can provide higher yields than others under the same reaction conditions.

Application of Fe Mo Catalyst for Formaldehyde

The iron-molybdenum formaldehyde catalyst is primarily used in the methanol-to-formaldehyde oxidation process via the iron-molybdenum method.

Our high-performance products serve as excellent alternatives to the iron-molybdenum formaldehyde catalysts produced by Haldor Topsoe, Johnson Matthey, and Clariant.

Specification of Fe Mo Catalyst for Formaldehyde

Physico-chemical properties

|

Item

|

SYAMCAT JQ116

|

SYAMCAT JQ216

|

SYAMCAT JQ316

|

|

Dimensions/mm(OD *ID*L)

|

4.7*2.0*4.7

|

4.7*2.0*3.0

|

4.7*2.0*4.7

|

|

Bulk density kg/L

|

0.84-0.92

|

0.86-0.92

|

0.82-0.90

|

|

Intensity N/particle

|

8-11

|

7-9

|

8-10

|

Mo/Fe atomic ratio | 2.4-2.6 | 2.4-2.6 | 2.4-2.6 |

Methanol conversion | ≥99.6% | ≥99.6% | ≥99.5% |

Formaldehyde yield | ≥93.2% | ≥93.0% | ≥93.0% |

Benefits of Fe Mo Catalyst for Formaldehyde

● High yields of formaldehyde, improving the conversions of methanol.

● Longer operating lifetime.

● Lower pressure drop, improving the stability and performance of catalysts.

● Stable operations with lower hot spot temperature concerns.

The activity of Fe Mo Catalyst for Formaldehyde

The activity is an important indicator to measure the performance of catalysts. If the activity is low, the reaction temperature need to be increased to maintain the high conversion rate.However,it will accelerate the deactivation of the catalyst and increase of by-products which reduced the yield of the product. SYAMCAT catalyst can completely convert methanol at lower reaction temperature, which is beneficial to reduce by-products and prolong catalyst lifetime.

The selectivity of Fe Mo Formaldehyde Catalysts for CO and CO2

The process of methanol oxidation to formaldehyde will generate a small amount of CO and CO2, which will affect the yield of formaldehyde and increase the unit consumption of methanol of the reaction raw material.To achieve the same high conversion rate, the catalyst with poor activity must have a higher reaction temperature, which leading to further deep oxidation of the product with generating more CO and CO2. SYAMCAT catalyst has the highest activity and the least generation of CO and CO2 .

Technical Service of Fe Mo Catalyst for Formaldehyde

The loading quality of the catalyst, the performance evaluation, strict operation and other technical managements are very important factors to prolong the service life of catalysts. So SYAMCAT will provide the technical services as follows,

●Loading of Fe-Mo catalyst

●Technical training

●Operation guidance