Revolutionizing Steam Reforming Catalysts: SYAMCAT's Breakthrough Innovation

- Share

- Issue Time

- Mar 19,2024

Summary

In the realm of steam reforming catalysts, SYAMCAT's research team has achieved a significant breakthrough with the successful development of the SYAMCAT Z433/Z434 series.

Revolutionizing Steam Reforming Catalysts: SYAMCAT's Breakthrough Innovation

Introduction:

In the realm of steam reforming catalysts, SYAMCAT's research team has achieved a significant breakthrough with the successful development of the SYAMCAT Z433/Z434 series.

Advanced Surface Modification: Enhancing Catalyst Resistance to Poisoning

Following an in-depth exploration of active components and carrier materials, SYAMCAT researchers employed an innovative surface modification technique. This approach introduced specific additives capable of inhibiting the adsorption and accumulation of toxic substances such as sulfur and chlorine on the catalyst surface. The resulting protective layer minimized direct contact between toxic substances and active sites, thereby preserving the steam reforming catalyst's activity and stability. Furthermore, the adoption of a novel composite oxide carrier not only bolstered thermal stability and mechanical strength but also reinforced the stability of the metal-carrier interface, thus enhancing resistance to poisoning.

Innovative Preparation Process: Crafting Uniform and Resilient Catalysts

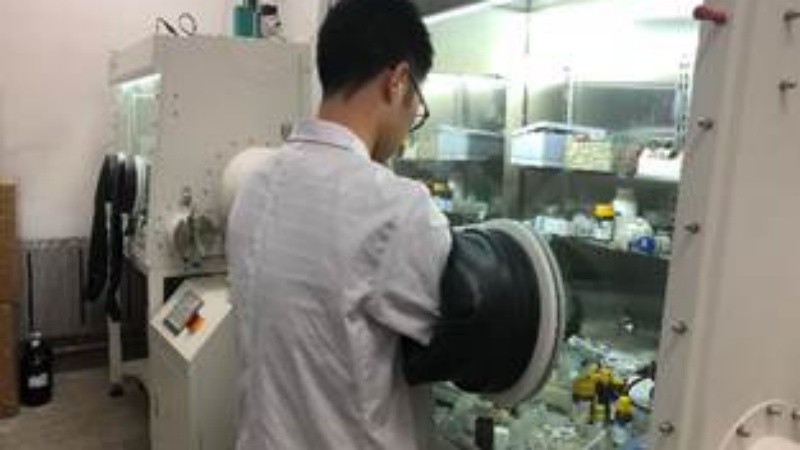

The preparation process was characterized by precision and innovation. Utilizing the sol-gel method, the research team ensured the uniform distribution of active components and additives on the carrier. Through the application of chemical vapor deposition (CVD) technology, anti-poisoning additives were introduced to form a uniform protective layer. Subsequent high-temperature calcination, conducted in an inert gas atmosphere, guaranteed the catalyst's thermal stability and structural integrity. Finally, reduction treatment in a hydrogen atmosphere activated the catalyst's active sites, ensuring optimal performance in practical applications.

Strategic Poisoning Experiments: Assessing Catalyst Resilience in Simulated Environments

To validate the catalysts' resilience, SYAMCAT researchers designed and executed a series of poisoning experiments. These experiments simulated the potential effects of sulfur, chlorine, and other industrial poisons, allowing for the observation of the catalysts' self-renewal capability. Additionally, the development of an in-situ regeneration method proved successful in restoring the activity of poisoned catalysts through specific chemical treatments and thermal cycling.

Conclusion: Industry Impact

The introduction of the SYAMCAT Z433/Z434 steam reforming catalysts not only underscores the SYAMCAT Corporation's leading technological position in the catalyst field but also offers a more reliable and economical solution for the synthetic ammonia and hydrogen production industries. The catalysts' exceptional resistance to poisoning not only reduces costs and enhances production efficiency but also minimizes environmental pollution, thereby injecting new momentum into the industry's sustainable development efforts.

Call to Action: Elevate Your Catalyst Requirements with SYAMCAT

For further inquiries and to experience the SYAMCAT advantage, please contact us.