Revolutionizing Hydrogen Production: SYAMCAT's Breakthrough Steam Reforming Catalysts

- Share

- Issue Time

- Mar 14,2024

Summary

SYAMCAT Z433/SYAMCAT Z434 steam reforming catalysts have outstanding advantages in anti-coking performance, injecting new impetus into the sustainable development of the synthesis gas industry.

Breakthrough in Low-Temperature Activity Technology for Ammonia Steam Reforming Catalysts

Introduction: Catalyst Innovation for Sustainable Hydrogen Production

SYAMCAT has developed a new type of steam reforming catalyst, SYAMCAT Z433/SYAMCAT Z434, which overcomes the problem of catalyst deactivation caused by the easier aggregation and greater carbon deposition of nickel-based catalysts, providing customers with a low-cost, high-performance steam reforming catalyst.

Innovative Catalyst Development: Overcoming Deactivation Challenges

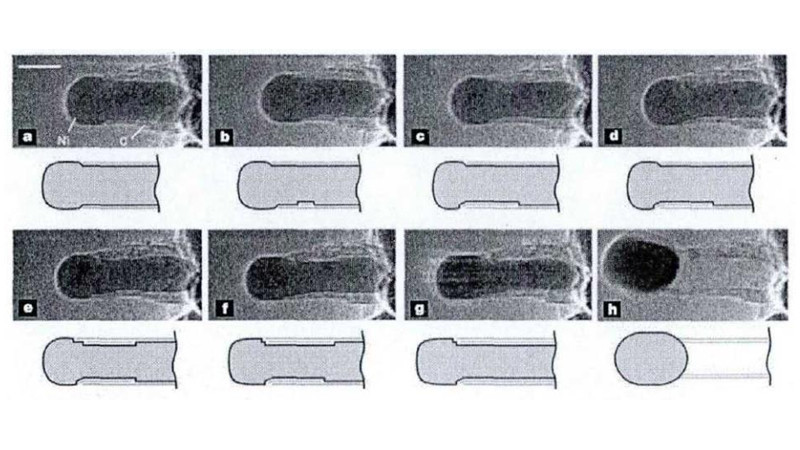

The research team at SYAMCAT found that Nickel, which has similar activity to precious metals, is still the preferred active component of steam reforming catalysts. Therefore, selecting suitable carriers and modifiers to kinetically inhibit carbon deposition has become a crucial aspect of catalyst development. Through continuous experimentation, the research team ultimately discovered a special modifier with exceptional structural stability and oxygen storage capacity, effectively inhibiting carbon deposition.

Development Process: Catalyst Synthesis and Rigorous Testing

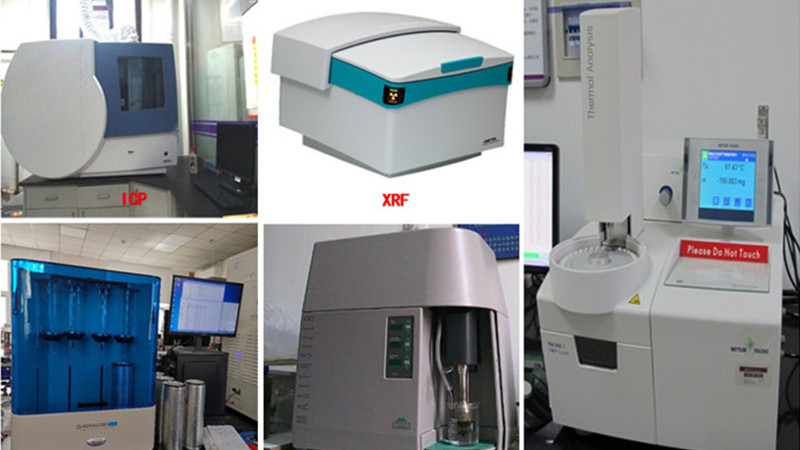

Researchers used Nickel as the active component, along with special modifiers and carriers, to obtain catalyst precursors with different component contents through stepwise impregnation. After reduction with high-temperature hydrogen, the steam reforming catalysts were synthesized, and their phase composition and elemental content were determined using XRD and ICP-AES.

Optimization Studies: Enhancing Anti-Coking Performance

Further research involved varying the Ni loading to find the optimal catalyst composition with the best anti-coking performance. Additionally, changes in catalyst loading, particle size, and gas flow rate were made to examine the effects of gas diffusion on catalyst performance and determine suitable catalyst testing conditions. Through techniques such as TG, XRD, SEM, CO2-TPO, and O2-TPO, the carbon deposition amount, structure, and activity of SYAMCAT Z433/SYAMCAT Z434 steam reforming catalysts were studied.

Conclusion: Empowering Industry Advancement with SYAMCAT Catalysts

Through persistent research efforts, the anti-coking performance of SYAMCAT Z433/SYAMCAT Z434 steam reforming catalysts has been significantly improved, providing customers with a more cost-effective choice.

SYAMCAT Z433/SYAMCAT Z434 steam reforming catalysts have outstanding advantages in anti-coking performance, injecting new impetus into the sustainable development of the synthesis gas industry. SYAMCAT continues to prioritize research and innovation, focusing on customer needs and providing better solutions for ammonia plants,hydrogen production and methonal synthesis plants with advanced scientific technology.

Call to Action: Elevate Your Catalyst Requirements with SYAMCAT

For further inquiries or to explore how SYAMCAT can revolutionize your catalyst requirements, contact us today.