Advancements in Ammonia Synthesis: Enhancing Efficiency with SYAMCAT Steam Reforming Catalysts

- Share

- Issue Time

- Feb 16,2024

Summary

With a focus on enhancing stability and performance, SYAMCAT steam reforming catalysts redefine the landscape of steam reforming catalysts, providing customers with reliable and stable production support.

Advancements in Ammonia Synthesis: Enhancing Efficiency with SYAMCAT Steam Reforming Catalysts

Introduction to Ammonia Synthesis and Catalyst Research

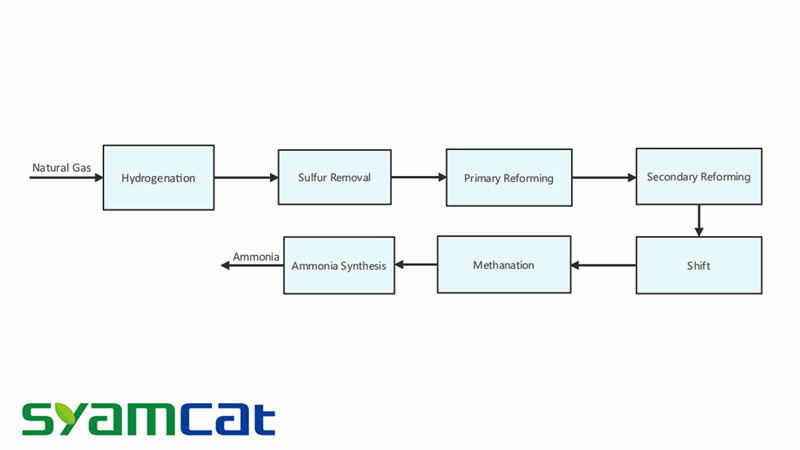

Ammonia synthesis plays a crucial role in various industries, leveraging natural gas as its primary feedstock due to its abundant reserves, simple molecular structure, and high atomic utilization efficiency. In this process, after desulfurization, natural gas is mixed with water vapor and fed into a primary reformer operating at 3.6 MPa and 834°C, where most of the methane undergoes conversion into hydrogen, carbon monoxide, and carbon dioxide using nickel-based catalysts.

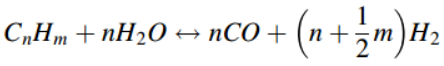

The Significance of Methane Steam Reforming

The essence of the primary reforming stage lies in the steam reforming reaction of methane. Methane reforming for hydrogen production offers advantages such as low cost, low carbon emissions, and wide availability of feedstocks, making it suitable for large-scale hydrogen production and providing ample hydrogen for subsequent ammonia synthesis processes.

The Role of Ni-Based Catalysts in Methane Steam Reforming

Nickel-based catalysts, such as Ni/Al2O3, are among the catalytic systems exhibiting excellent performance in methane steam reforming reactions. To prevent surface carbon deposition, alkali metal elements like sodium and potassium are often incorporated into these catalysts. However, challenges persist, including poor high-temperature stability, high nickel consumption, and limited active sites, underscoring the importance of design improvements in nickel-based catalysts for this reaction.

Research on Enhancing Stability of Ni-Based Catalysts

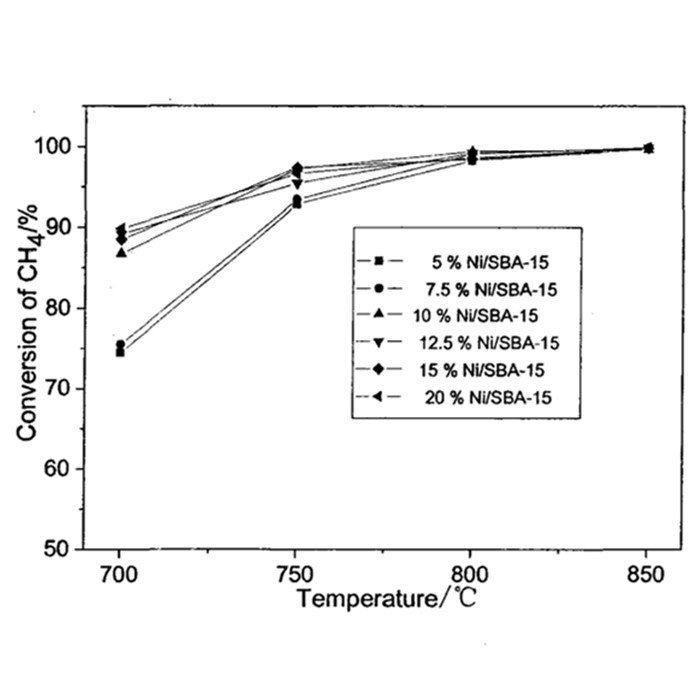

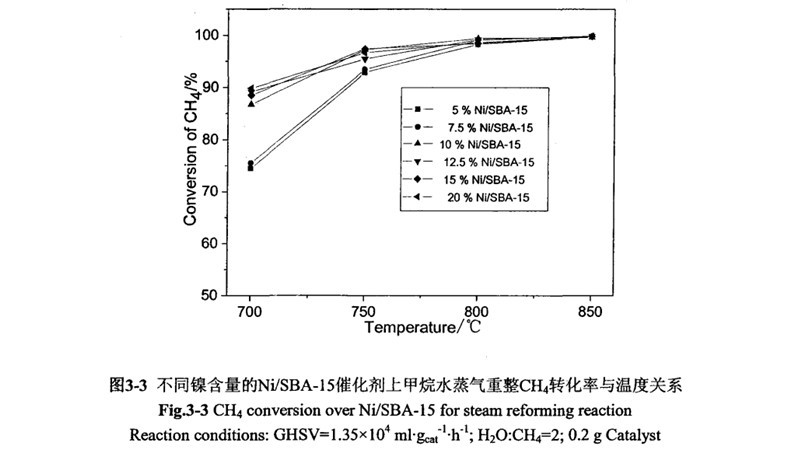

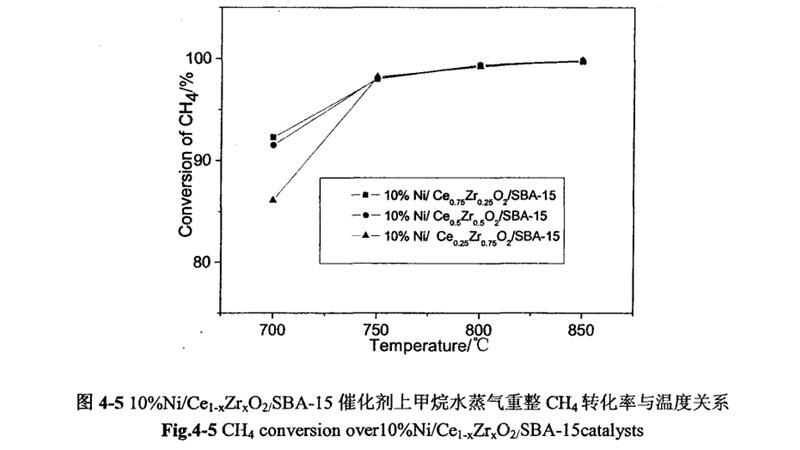

The research group led by Wan Huijun at Beijing University of Technology conducted studies on various catalysts to address the stability issues of nickel-based catalysts in methane steam reforming reactions. Their findings revealed that 10 wt% Ni/SBA-15 exhibited excellent activity and stability at 800°C, with no significant activity decline after 740 hours of reaction. Introducing the Ce1-xZrxO2 component enhanced nickel dispersion and improved the catalyst's oxidation-reduction performance and activity. Additionally, when FeCrAl was used as the support carrier, larger gas velocities could be employed under the same reaction conditions to achieve similar catalytic activity.

Innovation with SYAMCAT Steam Reforming Catalysts

SYAMCAT steam reforming catalysts represent a significant advancement in catalytic technology for ammonia synthesis processes. With a focus on enhancing stability and performance, SYAMCAT steam reforming catalysts redefine the landscape of steam reforming catalysts, providing customers with reliable and stable production support. Leveraging innovative anti-poisoning technology, these catalysts offer exceptional resistance to deactivation, ensuring sustained efficiency and productivity in ammonia synthesis operations. SYAMCAT's commitment to technological innovation continues to drive advancements in steam reforming catalysts, offering customers advanced and sustainable solutions to propel the ammonia industry forward.

Unlocking Future Opportunities with SYAMCAT Steam Reforming Catalysts

SYAMCAT is at the forefront of catalytic innovation, committed to providing cutting-edge solutions for the evolving needs of the industry. Our SYAMCAT steam reforming catalysts represent a leap forward in catalyst technology, offering unmatched stability and performance in ammonia synthesis processes. With a proven track record of excellence, SYAMCAT catalysts are trusted by industries worldwide to deliver reliable and efficient performance, even in the most demanding operating conditions.

Contact Us for Your Catalyst Needs

If you're seeking catalyst solutions tailored to your specific requirements, look no further than SYAMCAT. Our team of experts is ready to assist you in selecting the right catalyst for your project, ensuring optimal performance and efficiency. Contact us today to discuss your needs, and let SYAMCAT be your partner in driving success in ammonia synthesis and beyond.