Strategic Catalyst Procurement: A Comprehensive Guide for Ammonia Plants

- Share

- Issue Time

- Jan 30,2024

Summary

The catalyst procurement department in ammonia synthesis plants plays a critical role in ensuring the facility's operational smoothness and efficiency.

Strategic Catalyst Procurement: A Comprehensive Guide for Ammonia Plants

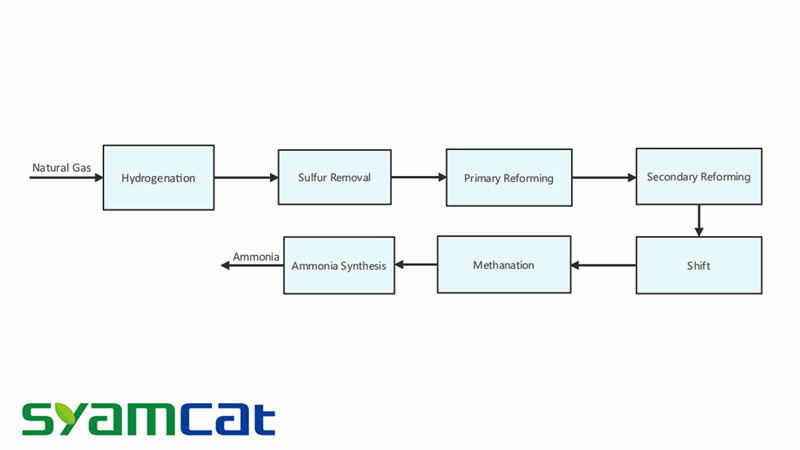

The catalyst procurement department in ammonia synthesis plants plays a critical role in ensuring the facility's operational smoothness and efficiency. This involves the acquisition of various catalysts, such as hydrogenation catalysts, zinc oxide desulfurization catalysts, steam reforming catalysts, high temperature shift catalysts, low temperature shift catalysts, methanation catalysts, and ammonia synthesis catalysts. Each catalyst type demands a thorough analysis of the operational conditions within the respective reactors to understand requirements and performance expectations.

Key Responsibilities of the Catalyst Procurement Department

Diverse Catalyst Procurement

Acquiring a variety of catalysts is essential for different stages of the ammonia synthesis process. This includes hydrogenation catalysts, zno desulfurization catalysts,primary and secondary steam reforming catalysts, high and low temperature shift catalysts, methanation catalysts, and ammonia synthesis catalysts.

Reactor Analysis and Monitoring

Analysis of Reactors: Conducting a thorough analysis of operational conditions in each reactor to understand catalyst requirements and performance expectations.

Conduct a detailed examination of reactor operational conditions, ensuring precision in understanding catalyst requirements. Implement robust monitoring systems to track catalyst performance continually, optimizing their efficiency within individual units.

Lifecycle Planning and Optimization

Strategically plan the lifecycle of each catalyst type, assessing replacement cycles for timely action and minimizing operational downtime. Collaborate with technical and engineering teams for troubleshooting and optimization, enhancing overall operational efficiency.

Quality Assurance and Collaboration

Environmental Compliance and Cost Efficiency

Storage, Handling, and Training Excellence

Regulatory Awareness and Emergency Preparedness

Stay abreast of evolving regulations related to catalyst materials and handling, ensuring compliance at local, national, and international levels. Develop comprehensive contingency plans for emergency situations, including spill response and effective communication strategies.

Benchmarking and Innovation

Regularly benchmark the performance of different catalysts against industry standards, driving continuous improvement initiatives. Actively engage in collaborative efforts with research institutions and catalyst manufacturers to explore innovative solutions, remaining at the forefront of technological advancements.

Sustainability Integration and Continuous Improvement

Integrate sustainability considerations into catalyst procurement strategies, exploring catalysts with reduced environmental impact. Contribute to the overall sustainability goals of the ammonia synthesis process through eco-friendly practices and continuous improvement initiatives.

Supplier Evaluation and Cost Analysis

Regularly evaluate the performance of catalyst suppliers, considering factors such as reliability, responsiveness, and consistency in delivering high-quality catalysts. Conduct comprehensive lifecycle cost analyses for different catalysts, considering not only initial procurement costs but also maintenance, replacement, and operational efficiency over the catalyst's service life.

Knowledge Transfer for Operational Excellence

Facilitate knowledge transfer within the procurement team, ensuring that insights gained from experience are shared across team members. Leverage collective knowledge to contribute to operational excellence in catalyst procurement practices.

By actively engaging in these responsibilities, the catalyst procurement department contributes to the overall efficiency, reliability, and environmental sustainability of the ammonia synthesis plant. Their role is pivotal in maintaining operational excellence and ensuring the plant's contribution to the production of ammonia for various industrial applications.

Leveraging SYAMCAT for Optimal Catalyst Solutions

In the realm of catalyst procurement, SYAMCAT emerges as a valuable partner for ammonia synthesis plants. Offering a range of innovative catalyst solutions, SYAMCAT stands ready to assist procurement departments in enhancing efficiency, reducing environmental impact, and ensuring the longevity of catalysts. With a commitment to excellence, SYAMCAT's cutting-edge technologies align seamlessly with the goals of ammonia synthesis plants, making it a strategic choice for those seeking reliable and sustainable catalyst solutions. As your plant's catalyst procurement partner, SYAMCAT envisions a future where efficiency and sustainability go hand in hand.

Contact SYAMCAT

If you have specific requirements or inquiries, please feel free to reach out to SYAMCAT. We are here to address your needs and collaborate on tailored solutions to optimize your catalyst procurement experience. Contact us for personalized assistance and discover how SYAMCAT can contribute to the efficiency and sustainability of your ammonia synthesis processes.